Vee Seals – Correct and Incorrect Features of Packing Seals

Posted by Tammy Soper on

Seals need to be made to have options in clearances if your going over or thru threaded surfaces or sharp projections. The clearance level needs to be made for the least amount tolerance in order for it to do it’s job. For every one thousandth of an inch that is added to the clearance that goes between the seal and the surface that it is sealing takes away the survival of the packing.

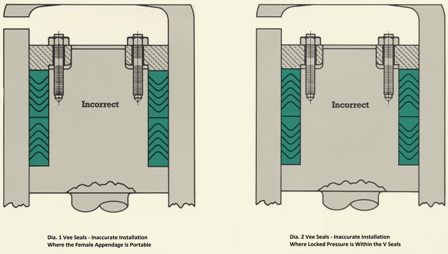

The correct schematic is vitally important when you are using sets of seals on the piston of double acting cylinder. Like in Dia. 1 where you have a female adapter that is movable which makes the load to have a direct response to relocate the the set of other seals after pressure has been utilized to the other side. Which it will be begin to have friction and wear on the seals.

In Dia. 2 it is not correct either in that it shows the pressure is closed in between the set of packing.

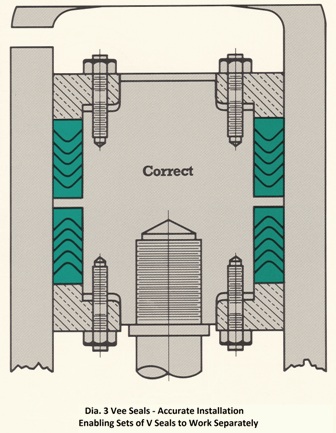

In Dia. 3 it will show a correct because the seals are put in back to back and don’t have to rely on each other in order to work and give the correct ratings for the task at hand.

If your using different kinds of vee seals, make sure they are the same angle, stack height and have the same outside radius.

If you need further information on these types of seals call us at

800-361-0068 or email us at sales@htsrepair.com