The Correct Fluid Density & Temperature For Different Operating Systems

Posted by Tammy Soper on

The right temperature for the hydraulic system to function and have the correct fluid temperature and density is the primary goal for your unit to do the job at hand.

When hydraulic fluid diminishes the temperature goes up as well in reverse, thus you need to take notice of both at the same time when doing a task.

When you have low fluid density you may experience parts destruction by not using the right grease. It may instigate higher than normal weakening of oil film and has the potential for high fluid thickness that will hurt the system parts through out the surface.

Most parts that you purchase have recommendations of the fluids to use and the density of the fluid for the kind of part it is. This is just general knowledge of using the fluid, it should be in the vicinity of 100 to 1000 centistokes. There are times when having it as high as 1000 is permissible for short time frames for start up reasons. For reaching relative operating performance is usually around 36 – 16 centistokes and 25 centistokes for lesser density.

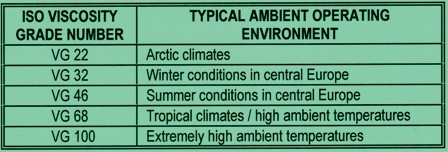

You will need the correct rating of fluid for your systems operating temperature selection. The chart will show the viscosity rating in centistokes. Also the ASTM and BSI are calculated at 100F*

If you need more information on different types of oils and there uses for different types of parts, call us at 800-361-0068 or email us at sales@hydrostatic-transmission.com