John Deere 655B/755B Crawler – Front Idler

Posted by Tammy Soper on

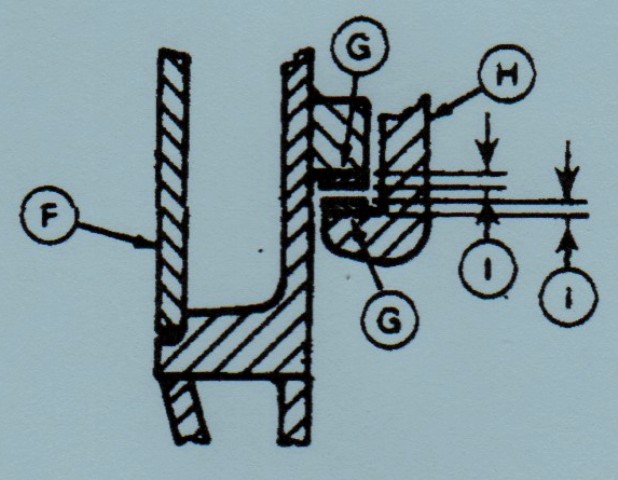

Make sure to put your crawler on about 6 inches above the ground to work on it. You then can look at the gap that is between the guide block assy and the wear strip that is on either side of the idler. Need to maximize the operating gap.

If you have a gap that goes beyond.120 inches, take off two cap screws. Prise up between the inner guide and guide block assy. Put in shims in between the top of the block and inner guide when you need to. Gap should be at 0-1 which is .040 inches.

If it goes to .120 inches the shim pack is needed., the J bar and lower track frame wear strips might have to replaced. Put in new wear strips if either or both strips goes below .120 inches thick. Put the shims, washers, cap screws and fasten the cap screws.

Also, If the front idler vertical gap is massive, you want be able to finish grade with the crawler and you could have track damage.

A – Gap .120 in max.

B – Block

C – Wear Strip

D – Cap Screws

E – Shims as needed

F – Track Frame

G – Wear Strip

H – Inner Guide

I – .120 min.

If you have further questions, call us at 800-361-0068

sales@htsrepair.com