Figuring Gear Pumps

Posted by Tammy Soper on

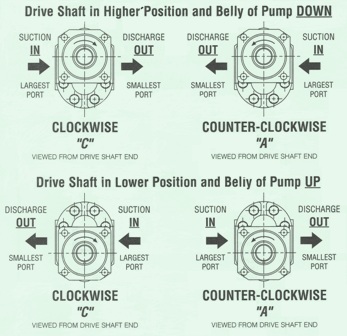

When you putting in another pump or motor, make sure you know all the major changes are accounted for. You will need to know the right system pressure, rpm range, direction of the rotation, shaft size/type, ports size/type and what kind of mount.

If you don’t know the correct rotation of your pump, it will damage your pump. Also, if you try to make these pumps do more than they are capable of, the life of the pump will be diminished. The inlet pump temperature doesn’t need to go over 225 F.

The pump inlet vacuum doesn’t need to go over 5 inches of mercury at operating temperature. You should use a pressure gauge on the outlet port to set the systems relief valve to the correct operating settings.

When you first put your pump on, it needs to run at the lowest rpm’s for first 5-10 minutes and gradually build up to make sure there are no leaks or build up heat.

If you have trouble with this, call us at 800-361-0068 sales@hydrostatic-transmission.com