Different Kinds of Telescopic Cylinders

Posted by Tammy Soper on

Extending a Cylinder

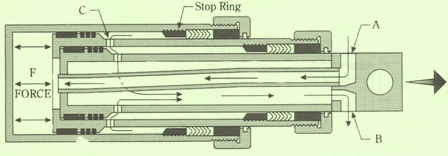

The high pressure oil goes thru the control valve into port A. Then it goes thru the transfer tube in the rod to the base of the cylinder where pressure moves on the area of the biggest piston and extends all stages to the first stop ring.

Following that the rod begins to extend. The area of the next stage is measured by the inside diameter of the up and coming biggest stage. Each of these stages extends its turn to the stop ring. The oil that is inside the sleeves goes out thru holes in each of the sleeves and goes back to the tank thru port B.

The oil goes to the control valve by way of port B. When pressure is put on the productive area of the plunger that retracts first, then each stage of the cylinder goes from the smallest to largest when it’s turn. Oil that is inside the cylinder is made to go of port A. That is due to the differential flow into port B that needs to be amplified by the differential to decide the flow out of port port A. You may need to put in a dump to tank valve to make this process go faster.

Viscosity – 50 SSU Minimum operating pressure/ 7500 SSU maximum operating temperature

150 to 225 SSU 100 degrees F/44 to 48 SSU 210 degrees F

Desirable Properties – viscosity index 90 min./Aniline Point 175 min.

Normal Temperatures – 0F to 100 F Ambient And use oil that is recommended for the temperature you expect to use on a particular job.

Additives that are usually recommended are that is needs to have rust and oxidation inhibitors and foam depressant.

Should be able to separate water, air and contaminants. Should be able to resist sludge, acids, tars and varnishes.

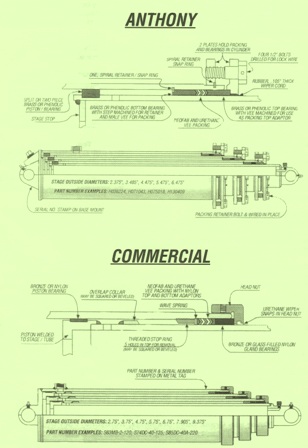

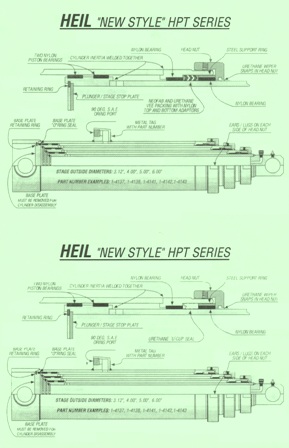

Here are other types of cylinders

If we can assist further with questions on cylinders, give us a call at 800-361-0068

sales@hydrostatic-transmission.com